In high-speed manufacturing environments, there’s no margin for error, especially when critical systems are isolated from the internet. This transportation leader needed a way to move operational data securely without compromising production speed or regulatory compliance. With thousands of engineering workstations and HMIs spread across multiple sites, traditional endpoint tools simply fell short. The real challenge was enabling safe, controlled USB usage across a distributed, air-gapped environment without introducing complexity or slowing teams down.

A New Layer of Defense

According to OPSWAT’s 2025 Threat Landscape Report malware complexity has jumped 127% in the last six months while file-based attacks remain one of the most persistent and evasive threat vectors targeting critical infrastructure.

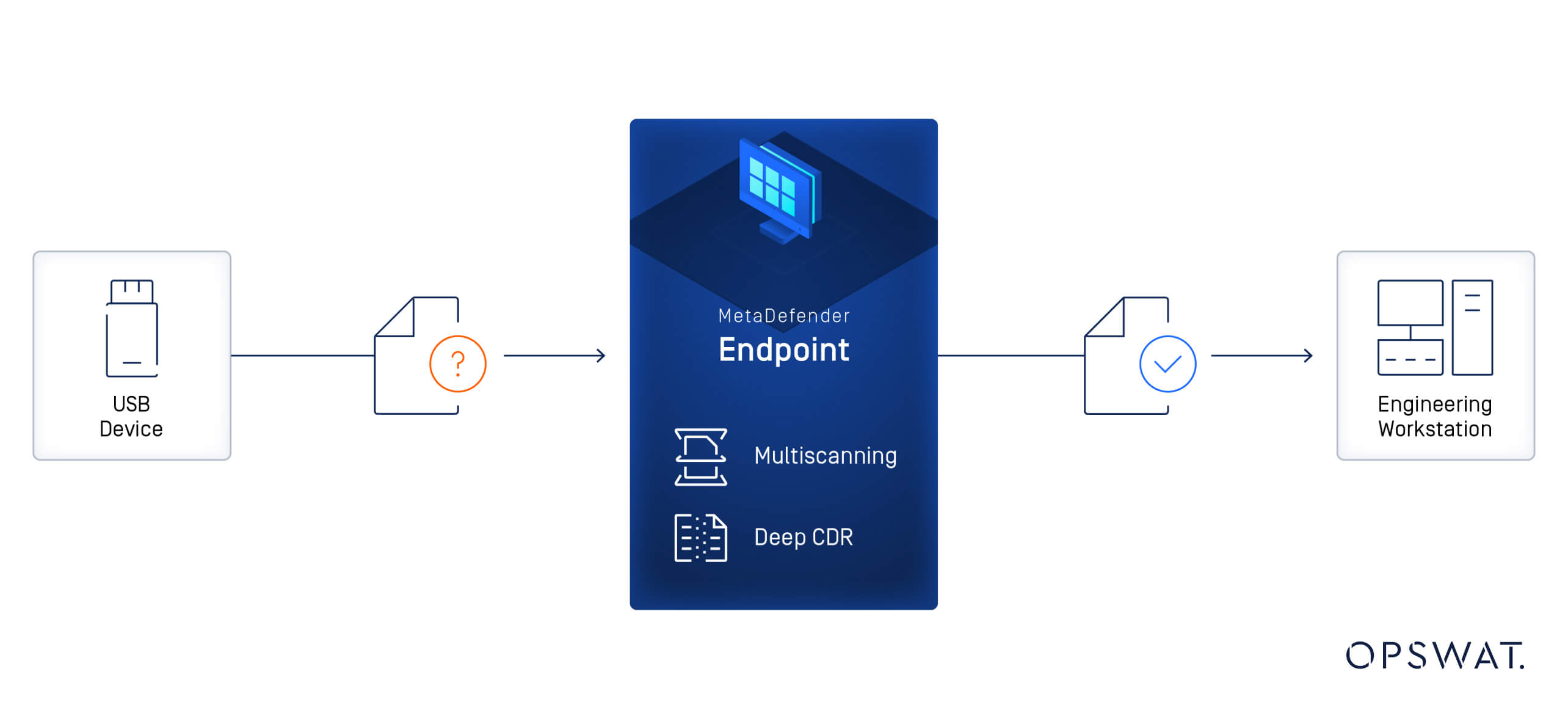

To mitigate these types of cyberattacks, protect its operations and close critical security gaps, the company turned to OPSWAT MetaDefender Endpoint. This on-premises solution was deployed directly to workstations, making it ideal for the company’s air-gapped network architecture. By introducing policy-driven media control at the endpoint, the company gained visibility, compliance support, and control without slowing operations.With Peripheral Media Protection, MetaDefender Endpoint blocks access to USB drives until they are scanned and found clean. Files are checked using advanced Metascan™ Multiscanning, which can leverage over 30 anti-malware engines to detect both known and unknown threats.

This multi-layered defense approach offers a detection rate far higher than any single antivirus product, which often misses threats in air-gapped systems due to limited behavioral analysis and lack of internet connectivity. Suspicious content is then sanitized using Deep CDR, which removes embedded threats without affecting file usability.

MetaDefender Endpoint helps close the security gaps that traditional endpoint protection tools often leave open, especially when it comes to controlling and inspecting data transferred via USB drives and other removable media. By adding this extra layer of control and threat prevention, it enhances the company’s existing defenses without requiring changes to the underlying infrastructure.

This combination gave the manufacturer something it hadn’t had before: complete control over removable media usage in an air-gapped environment without requiring changes to the existing infrastructure.

Safe Transfers, Strong Compliance, Uninterrupted Production

With MetaDefender Endpoint in place, the company eliminated the uncertainty that came with USB-based file transfers. Staff can now safely move operational data between systems, knowing every file is verified, clean, and compliant.

Key benefits:

- Production teams remain efficient

- Security teams gain visibility and control

- Compliance officers get the audit trails they need

Many global regulations now require organizations to enforce removable media protection and use multiple antivirus engines for file scanning, making these controls not just practical but essential. With OPSWAT, the company strengthened its compliance security posture.

Administrators now manage thousands of endpoints through the centralized management console. Now, they can define custom policies at a granular level and generate compliance reports with detailed scan history and risk posture data for easier audits and stronger policy enforcement. The system works quietly in the background, enforcing file hygiene without slowing down production.

Most importantly, operational efficiency and day-to-day workflows were preserved. Updates and configuration files can now be transferred safely, keeping manufacturing processes running smoothly while maintaining strict regulatory standards.

| Previous Challenges | OPSWAT MetaDefender Endpoint | |

|---|---|---|

| Peripheral Media Data Transfer | Manual, unverified USB/removable media usage | Scanned and sanitized before access |

| Peripheral Media Usage Visibility | Low visibility into device and file activity | Centralized, auditable logs and monitoring |

| Compliance with Media Usage | Risk of policy or regulatory violation | Built-in reporting and support for industry regulations |

| Production Impact | At risk from potential malware or downtime | Fully maintained with safe, approved media access |

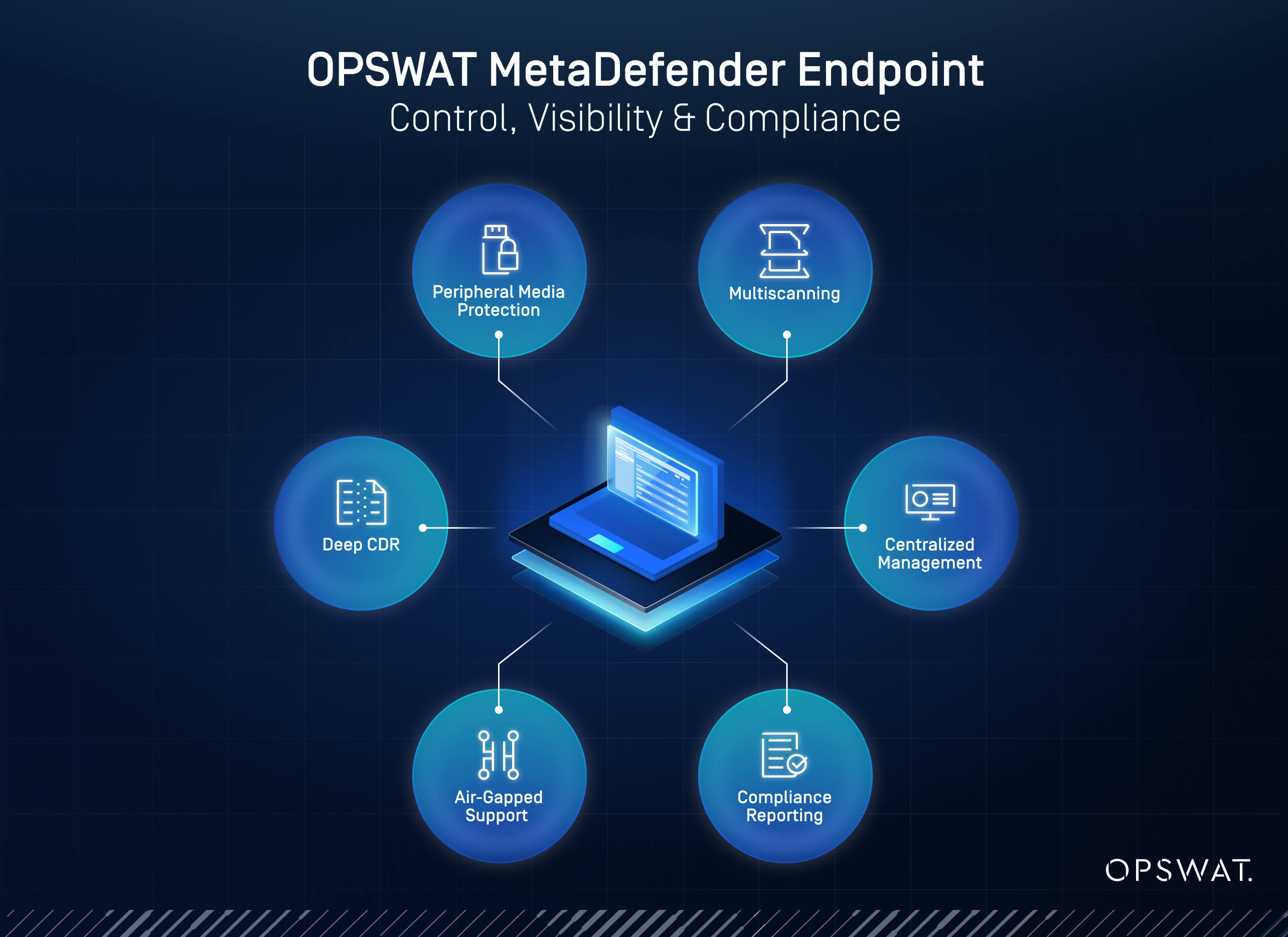

Delivering Control, Visibility & Compliance

OPSWAT MetaDefender Endpoint technologies and tools used in this deployment:

- Peripheral Media Protection: Enforces scanning policy for USB and other removable media, ensuring devices are scanned before use and that only clean files are accessible

- Metascan™ Multiscanning: Scans files with 30+ antivirus engines to detect known and unknown threats with significantly higher accuracy than single-engine tools

- Deep CDR™: Removes potentially malicious content while preserving the original file’s usability and format

- Centralized Management Console: Provides unified visibility and control, allowing administrators to set scanning rules, monitor device usage, and manage endpoint security across all locations

- Air-Gapped Network Support: Fully functional in offline environments, ideal for regulated or isolated systems

- Compliance-Ready Reporting: Automatically logs scan results, device activity, and threat detections to support internal audits and alignment with industry standards

Securing the Next Vulnerable Link in Critical Environments

By securing USB drives in offline production zones, this global manufacturer has reinforced its operational resilience. It’s a reminder that in high-stakes production environments, even simple file transfers can become a point of risk or a point of control.

To learn how MetaDefender Endpoint can protect your air-gapped or regulated environment, talk to an expert today.