Every minute of every day, pharmaceutical and biotech manufacturing facilities worldwide produce the medications that keep millions of people alive. Cancer treatments. Insulin. Antibiotics. Vaccines that prevent pandemics. Cardiovascular drugs. Immunosuppressants that make organ transplants possible.

Yet pharmaceutical manufacturing operates under constraints unlike any other sector. A single compliance deviation—whether in documentation, traceability, or contamination control—can trigger regulatory action, product recalls, or shutdowns that cascade into drug shortages affecting thousands of patients.

The industry has long focused on physical contamination control such as airlocks, cleanrooms, and validated processes. But a new form of contamination now threatens pharmaceutical manufacturing with equal severity: cyberattacks that can halt production, steal billions in intellectual property, and disrupt the supply chains that patients depend on for survival.

Healthcare and pharmaceutical organizations now face an average of 1,410 attacks per week per organization—a 69% increase over prior years. With manufacturing downtime costing up to USD 260,000 per hour, even a minor breach can cascade into catastrophic losses. Traditional defenses like air-gapped systems and firewall-based DMZs are no longer sufficient to protect complex production networks from today's sophisticated threats.

MetaDefender NetWallTM data diodes and security gateways provide a purpose-built solution: secure, hardware-enforced, one-way data transfer that enables essential information flow without introducing network risk. It empowers manufacturers to maintain compliance, protect intellectual property, and ensure uninterrupted production — all while advancing digitalization initiatives safely.

Why Pharmaceuticals Need Stronger Data Security

Most pharmaceutical plants continue to rely on traditional firewall-based DMZs (demilitarized zones) to protect critical manufacturing systems. While these worked adequately in simpler times, they create bidirectional pathways that sophisticated attackers can exploit. The result is a false sense of security that leaves production systems vulnerable to lateral movement attacks.

Despite being the gold standard for critical infrastructure protection, unidirectional gateways (data diodes) remain rarely deployed in pharmaceutical environments. These hardware-enforced, one-way data transfer devices physically prevent cyberattacks from reaching protected systems—yet adoption rates remain stubbornly low across the industry.

Modern pharmaceutical operations face mounting pressure from multiple directions. Supply chains now span continents with intricate webs of suppliers, contract manufacturers, and distributors. Simultaneously, pharmaceutical production must maintain absolute compliance with FDA, EMA, and GMP (Good Manufacturing Practice) standards that demand perfect documentation, complete traceability, and zero tolerance for contamination. This complexity creates more attack surfaces and more opportunities for security failures.

Cyberattacks in Pharma & Biotech: The Risk is Real

For years, cybersecurity in pharmaceuticals has been treated as a theoretical concern. Two major incidents — separated by just six years — reveal how quickly the threat landscape has evolved.

| 2017: Merck & NotPetya | 2023: Sun Pharma & ALPHV | |

|---|---|---|

| Attack Type | Collateral damage from a global ransomware outbreak | Targeted ransomware extortion |

| Impact |

|

|

| Implications | Exposed supply chain vulnerabilities and reliance on public health interventions | Highlighted IP value and extortion risks tied to patient safety |

| Key Lesson | Even indirect attacks can cripple pharma operations | Cybercriminals now deliberately target pharma’s most valuable assets |

Key Takeaway: Cyber Risks Are No Longer Hypothetical

These incidents shattered the illusion that pharmaceutical facilities are somehow insulated from cyber threats.

- Patient safety is directly threatened when manufacturing disruptions delay critical medications

- Revenue impact runs into billions when facilities go offline for extended periods

- Regulatory compliance is jeopardized when data integrity cannot be guaranteed

- Intellectual property theft undermines competitive advantage and years of R&D investment

- Supply chain disruption can create shortages that affect millions of patients

MetaDefender NetWall Use Cases for Pharmaceuticals

1. Protecting Intellectual Property

Challenge: Drug formulations, clinical trial data, and manufacturing processes represent billions in R&D investment. When Sun Pharma was hit by ALPHV ransomware, 17 TB of proprietary data was stolen.

Solution: MetaDefender NetWall’s hardware-enforced data diode and security gateway enables secure, one-way transfer of sensitive information from production or research networks to corporate or partner environments. By physically eliminating inbound connectivity, this diode-based gateway reduces the risk of espionage, data theft, and unauthorized access to mission-critical IP.

2. Regulatory & Compliance Reporting

Challenge: FDA 21 CFR Part 11 requires tamper-proof electronic records and signatures. Legacy systems often lack adequate data integrity controls, creating compliance risks during inspections.

Solution: As a compliance-ready data diode, MetaDefender NetWall ensures that data is exported in a reliable, tamper-proof manner while preserving the isolation of validated production systems. By creating a unidirectional reporting pathway, NetWall helps maintain data integrity, traceability, and audit readiness — essential for passing FDA and EMA inspections.

3. Secure File Backups

Challenge: Merck's NotPetya attack cost $1.3 billion partly because ransomware encrypted critical manufacturing data. Traditional network backups are vulnerable because malware can follow network connections to backup servers.

Solution: MetaDefender NetWall supports secure, diode-based backup workflows by transferring essential data to backup or disaster-recovery environments without exposing core production networks. Even if ransomware breaches IT systems, the one-way gateway ensures that critical OT data remains intact and recoverable.

4. Production Data & Batch Reporting

Challenge: Enterprise systems need real-time manufacturing data for planning and analysis, but every bidirectional connection creates attack surface that could expose production systems.

Solution: Using hardware-enforced unidirectional transfer, MetaDefender NetWall securely moves batch records, equipment performance metrics, and quality data from MES systems to ERP and analytics platforms. This OT-IT gateway gives business systems the visibility they need — without ever exposing production networks to inbound threats.

5. Historian Data for Analytics

Challenge: Process historians (AVEVA PI, OSIsoft, Honeywell PHD) contain decades of valuable manufacturing data. Data scientists need this for AI/ML projects, but connecting historians to enterprise networks creates massive security exposure.

Solution: MetaDefender NetWall functions as a data diode bridge, replicating historian data from OT networks to corporate IT environments or third-party analytics platforms in a one-way, hardware-controlled manner. This enables advanced monitoring and predictive analytics while maintaining the highest level of isolation for production systems.

6. Centralized Logging & Security Visibility

Challenge: Security operations centers need visibility into manufacturing networks to detect threats, but traditional SIEM agents create bidirectional pathways that attackers can exploit.

Solution: MetaDefender NetWall forwards syslog, Splunk data, and security events from manufacturing systems to centralized monitoring platforms outbound only. This security gateway ensures SOC teams get the visibility they need while preventing attackers from pivoting through SIEM infrastructure into production networks.

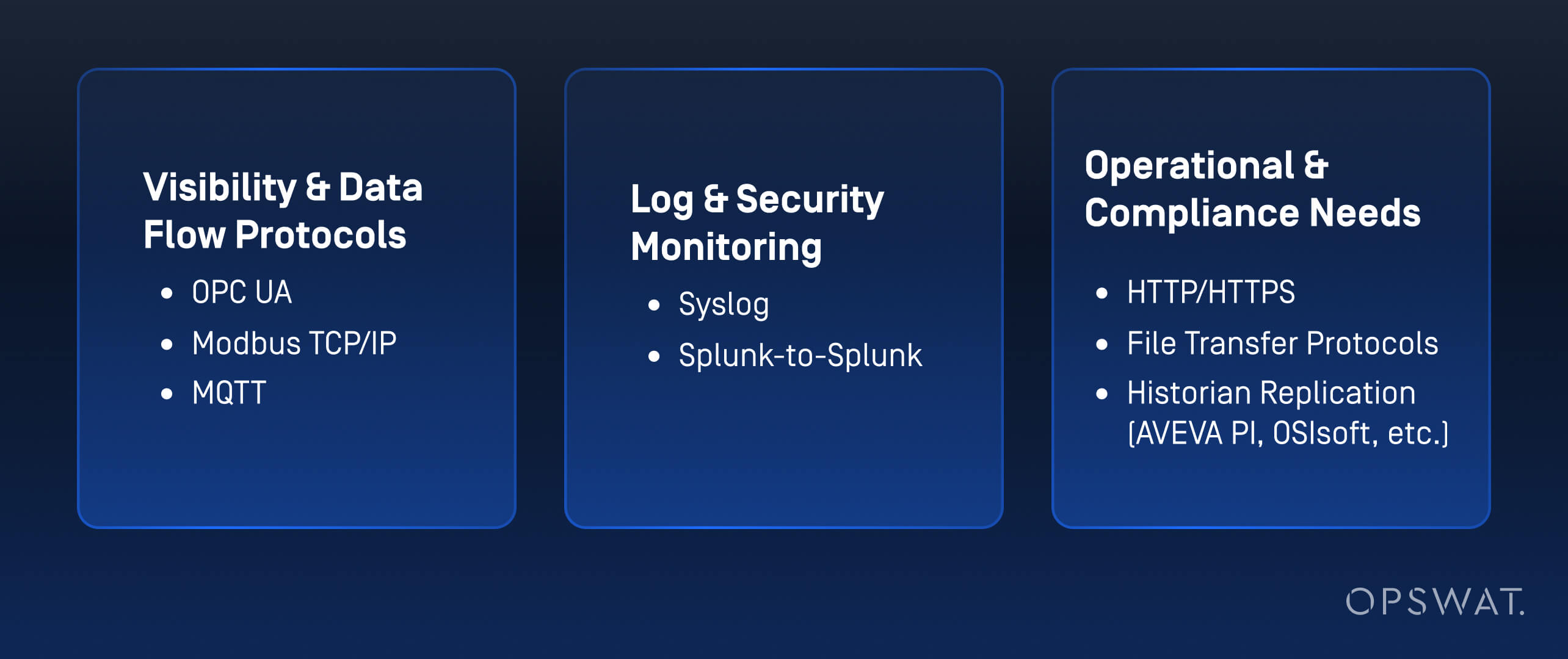

Supported Protocols: Technical Credibility

Pharmaceutical manufacturing environments rely on a diverse range of protocols to support production operations, regulatory reporting, and security monitoring. MetaDefender NetWall is designed to seamlessly integrate into these mixed IT/OT ecosystems, providing hardware-enforced one-way data transfer without requiring disruptive architecture changes.

This comprehensive protocol support means MetaDefender NetWall integrates seamlessly into existing pharmaceutical infrastructure without requiring disruptive architecture changes or equipment replacements.

Benefits of Deploying MetaDefender NetWall in Pharma & Biotech

Regulatory Alignment

MetaDefender NetWall’s tamper-proof, diode-enforced data transfer supports compliance with GMP requirements and regulatory standards from agencies such as the FDA and EMA. It helps maintain data integrity, traceability, and audit readiness while protecting validated production systems from unauthorized access.

Operational Continuity

Cyber incidents such as ransomware or malware propagation can halt production and jeopardize patient supply chains. By establishing a hardware data diode between OT and IT, MetaDefender NetWall blocks inbound threats and prevents malware propagation, reducing the risk of production shutdowns and safeguarding patient supply chains.

Risk Reduction

MetaDefender NetWall safeguards high-value assets, including proprietary formulations, batch records, and automation systems. It also helps maintain uninterrupted supply of essential medicines by protecting the digital backbone that underpins production, quality control, and logistics operations.

Future-Proofing for Digital Transformation

As pharma operations embrace IoT, AI, and cloud analytics, secure, diode-based data sharing becomes essential. NetWall’s scalable architecture ensures organizations can adopt new technologies without compromising security or compliance.

Protect your operations, your data, and your patients.

MetaDefender NetWall gives pharmaceutical and biotech manufacturers a secure, diode-based way to share data, meet regulatory demands, and prevent billion-dollar outages — all without disrupting operations.

Contact OPSWAT to assess your risk profile and explore how MetaDefender NetWall can strengthen your manufacturing environment.